About Motorcycle Parts New Zealand Specialists

Table of Contents4 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists for BeginnersWhat Does Motorcycle Parts New Zealand Specialists Do?Examine This Report on Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists StatementsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThe 10-Second Trick For Motorcycle Parts New Zealand Specialists

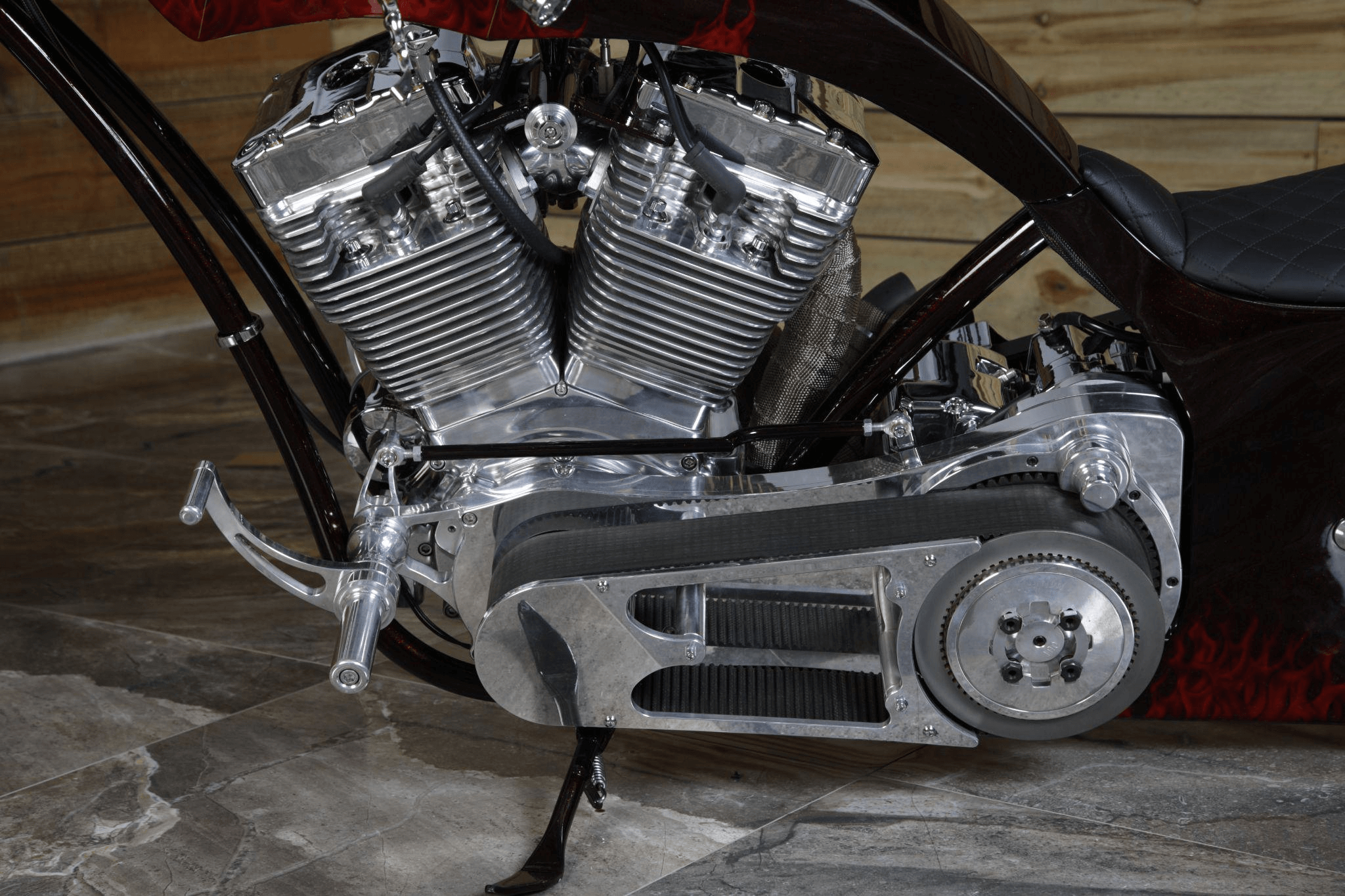

So, get to out to one of our experts today.CNC machining technology is rapidly ending up being the prime focus of various manufacturing processes around the globe as a straight result of its numerous advantages over other techniques. Furthermore, the markets that manufacture bikes have jumped on board with this fad. The most ingenious business are currently developing their engine components and wheels utilizing machining methods initially developed for motorcycle parts.

On the other hand, the results of market are the primary focus of this post. Let's obtain right right into it. You may be wondering why we utilize. It is not tough to fathom the elements that caused this result. Now that we have your interest allow us describe the rationale behind this contemporary advancement in the motorcycle manufacturing industry.

Little Known Questions About Motorcycle Parts New Zealand Specialists.

In addition, you have total control over the look of the components, even down to the min details. Sometimes, motorcyclists may decide to improve their ride by installing aftermarket components or customizing the bike's remodeling. As soon as once again, computer system numerical control (CNC) machining is one of the most practical technique. Upgrades might be of any type of type and design you desire.

The Only Guide to Motorcycle Parts New Zealand Specialists

CNC machining may be utilized to make nearly all of a motorbike's steel and plastic parts. To proceed, we'll talk about several machined components for bikes. In contrast to those on autos, wheels on motorbikes have a tendency to be much more noticeable. Therefore, the bike's appearances may be boosted with the ideal personalization of these wheels.

Milling procedures are used to acquire the preferred degree of wheel modification. An additional element of the motorcycle that may be customized is the tires.

The Only Guide to Motorcycle Parts New Zealand Specialists

When it concerns a lorry (or a motorcycle), the most vital component is the engine. Several individuals suggest to it as the "heart" of the automobile. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and require styles with a high level of precision.

Lighting is one more complicated facet of modification. Use just top notch items, however, since these lights are vital for the security of motorcyclists and various other motorists or individuals when driving, especially during the night. Motorbike headlights have 3 major components: the bulb, or light, the lens, and the housing. In particular, we customize the lens and the real estate.

Milling processes with a remarkable surface would certainly result in the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of breakable products; rather, it is created out of hard polymers that can be machined right into even more elaborate patterns.

Getting My Motorcycle Parts New Zealand Specialists To Work

They typically have sophisticated geometries with a wide range of minute information. Bike makers commonly cast these parts, however just for the production of bespoke components. Nevertheless, CNC machining is the technique of selection when producing special items. Machining on 5 axes in today's globe is the ways through which any type of layout form may be realized.

The success of the procedure is contingent on the mill cutters' ability learn this here now to compute subtle and complex angles accurately. Pick Runsom for your personalized bike parts! We have the capacity to produce difficult and elegant components making your motorcycle incomparable. The majority of are crafted from aluminum or steel alloys, each of which has its uses and advantages.

Below are a couple of examples of steels frequently used in bike element machining. Light weight aluminum is the main material used by companies specializing in creating custom-made motorbike components to create many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes one more metal that is very light in weight and has great machining qualities due to its high mechanical toughness. This material may be formed right into nearly any type of shape and maintains its dimensions well. Even mission-critical parts that need a high degree of accuracy might take advantage of their usage.

The Buzz on Motorcycle Parts New Zealand Specialists

One more metal that sees hefty usage in the manufacturing of CNC-customized components is magnesium. It is amongst the lightest metals that are now obtainable and has excellent machinability attributes and stamina proportionate with its reduced weight. One of the drawbacks of magnesium is that its dirt might quickly capture fire.

Their most common usage in producing different bike parts is fasteners, top article such as screws and screws. Their low susceptibility to oxidation and deterioration makes them optimal for this usage.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and grating are the foundational processes. In enhancement, it requires maintaining bars of product, most often plastic or metal, in setting and then turning a reducing tool to eliminate areas of the product as the product is turned.

These approaches are equally important and produce parts with high accuracy and regular top quality. The procedures assist improve the total quality of the machined motorcycle site web elements.

The Facts About Motorcycle Parts New Zealand Specialists Revealed